Precision Injection

Molding.

Trusted By Industry Leaders

Trusted by these partners for 10+ years.

The Parshwa Standard

Why Industry Leaders

Keep Reordering.

Owner‑Led Responsiveness

Direct line to the founder. Same‑day replies during NA & EU business hours. No ticketing queues, just answers.

Zero-Risk Second Sourcing

First-Lot Fit Guarantee: If any critical dimension is off-spec, we remake and rush-ship at our cost. Perfect for overflow.

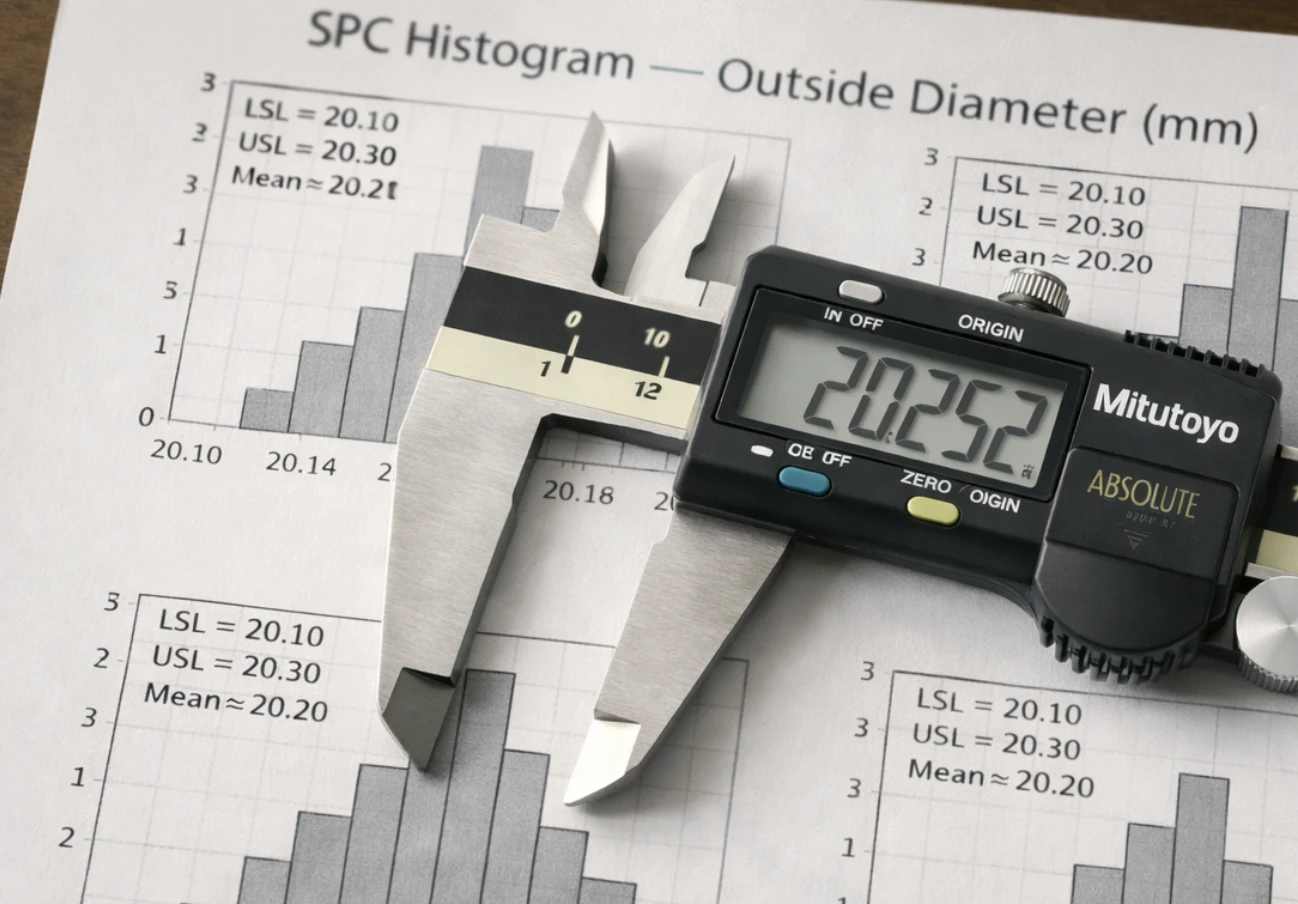

Documented Quality Control

SPC and control charts included with every delivery. Optional third-party inspection from accredited labs available.

Turnkey Manufacturing

From insert molding to final packaging. We handle sub-assembly, labeling, and export-ready kitting.

Scalable Production

Ramp from 100 to 100,000+ parts without quality drift using our dedicated in-house presses and vetted partner network.

Precision Focused

Specialists in small parts (<100g) with typical tolerances of ±0.10mm. We prioritize yield and schedule integrity.

Manufacturing Capabilities

From complex geometries to high-performance materials, our facility is equipped to handle the most demanding injection molding challenges.

Precision Molding

Servo-electric presses providing tight control on small parts. ±0.1 mm typical; ±0.05 mm achieved on specific programs.

Insert & Over-Molding

Complex metal or plastic inserts, soft-touch (TPE), and multi-material shots for sealed electronics and ergonomic grips.

Advanced Materials

Expertise in engineering-grade resins including PA6/66, POM, PC, and specialty glass-filled grades with full lot traceability.

Finishing & Aesthetics

Surface textures per VDI/Mold-Tech standards. Precise color matching to Pantone or master chips before production begins.

Turnkey Value-Add

Complete post-molding services including hardware installation, sub-assembly, kitting, labeling, and export-ready packaging.

Material Science

Raw Material Expertise

We process a wide range of engineering-grade resins, sourced from authorized distributors with full lot traceability.

Nylon 6 (PA6)

Versatile engineering plastic with high mechanical strength and toughness.

- Natural & Black

- 15% Glass Filled

- 30% Glass Filled

- MoS2 Filled

Nylon 66 (PA66)

Superior temperature resistance and mechanical properties compared to Nylon 6.

- Natural & Black

- 15% Glass Filled

- 30% Glass Filled

Delrin / POM

High stiffness, low friction, and excellent dimensional stability.

- Natural & Black

- 15% Glass Filled

- 30% Glass Filled

Specialty Resins

Broad range of high-performance polymers for specific application requirements.

- Polycarbonate (PC)

- Polyurethane (PU)

- PVC

- ABS

- Polypropylene (PP)

From CAD to Components

A transparent, documented process designed for speed and reliability.

RFQ & Scope Lock

Send your files. We acknowledge same-day, identify gaps, and lock scope including 3D/2D tolerances, resin, finish, and packaging.

Comprehensive Quote

Decision-ready pricing in your currency (USD/CAD/EUR). All assumptions and risks clearly documented, not buried in fine print.

Tooling & DFM

We cut steel only after DFM sign-off. Weekly progress updates with photos/videos. Molds stored securely for the life of the program.

T1 Sampling

T1 parts couriered with inspection reports on critical dimensions. You get physical parts to validate fit and function.

Production & QC

Controlled production run. 100% inspection on criticals. SPC charts provided. First-Lot Fit Guarantee ensures zero risk.

Global Delivery

DAP worldwide. We handle export packaging, labeling, and customs documentation. Tracking provided proactively.

Precision Portfolio

A selection of components manufactured to exact specifications.

Ready to Manufacture?

Skip the brokers and the uncertainty. Get direct-to-manufacturer pricing with owner-led accountability.